I did a little digging. Last night I just saw a fairly modern pipe holder. Today I found that this could be a long search.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mystery tool

- Thread starter xtratoy

- Start date

Help Support Ruger Forum:

caryc

Hawkeye

Using a rivet set when fastening together 2, 3 or maybe 4 pieces of metal. You would give the end of the rivet a light smack to tighten it in the hole a bit, then you would place the hole over the rivet to drive all the pieces down on the rivet head before actually setting the rivet with a hammer or a gun.Doesn't look like any rivet punch I've ever seen. Most of those have a hole to cut the rivet to correct length for head forming.

Or is the term a "rivet set"?

Bob Wright

xtratoy

Buckeye

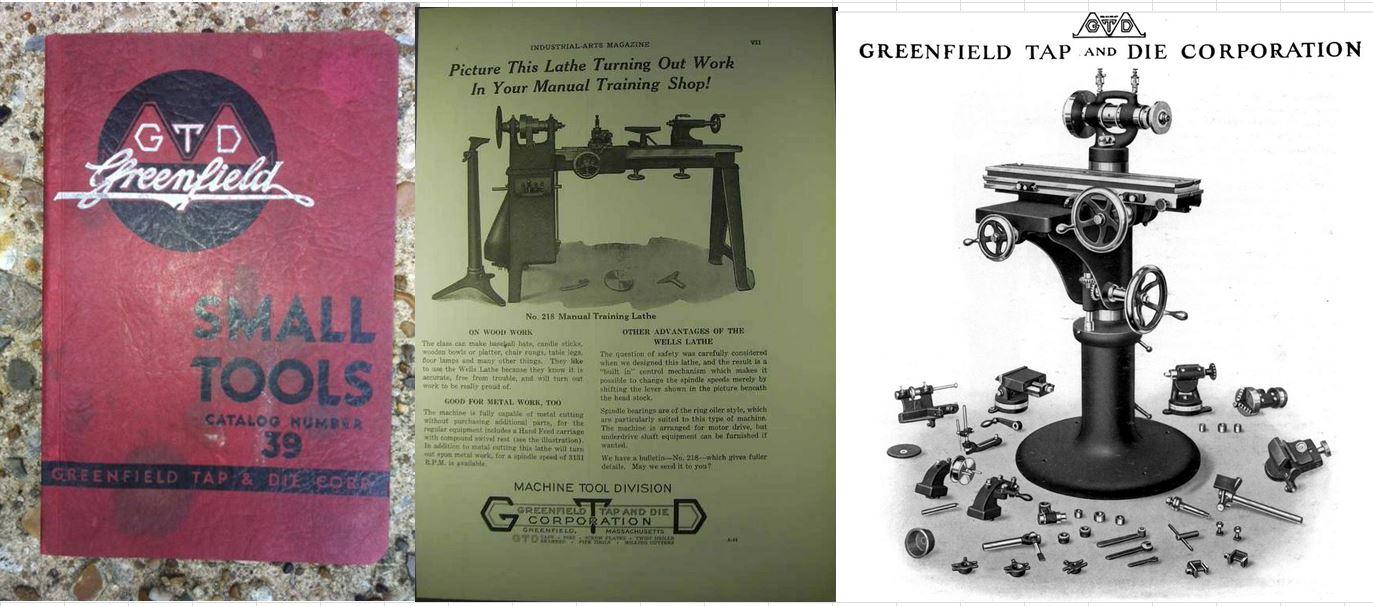

Interesting.. I am still waiting to see if Greenfieldresponds to my email query.I did a little digging. Last night I just saw a fairly modern pipe holder. Today I found that this could be a long search.

View attachment 45417

When grinding a precision taper, especially in the days before modern computer assisted CMM's, you would check the paper for correct included angle with a taper gage. You could lightly wipe on hi spot bluing (Prussian Blue) and see if it transfers evenly. If it make a blue ring at the bottom the taper angle is too large if a ring at the top the angle is too small. If correct you get an even transfer and if the finish is smooth enough the gage will almost lock into place. like a morse taper for tools. Once the angle is correct you can grind for size and the gage generally has two steps for min and max. You would want the gage to stop with the suface face between the two steps.

I believe that is a taper gage.

I believe that is a taper gage.

Cylindrical Taper Plug Gage - Morse

Cylindrical Taper Plug Gage - Morse WESTport Gage manufactures a complete line of standard taper ring and taper plug gages;Morse, Jarno, Brown & Sharpe, Jacobs, National Machine and any other special taper gage made to your blueprint specifications. WESTport also manufactures tapered arbors to...

westportcorp.com

xtratoy

Buckeye

That is highly likely a correct description of what this does. It looks like one in the picture.When grinding a precision taper, especially in the days before modern computer assisted CMM's, you would check the paper for correct included angle with a taper gage. You could lightly wipe on hi spot bluing (Prussian Blue) and see if it transfers evenly. If it make a blue ring at the bottom the taper angle is too large if a ring at the top the angle is too small. If correct you get an even transfer and if the finish is smooth enough the gage will almost lock into place. like a morse taper for tools. Once the angle is correct you can grind for size and the gage generally has two steps for min and max. You would want the gage to stop with the suface face between the two steps.

I believe that is a taper gage.

Cylindrical Taper Plug Gage - Morse

Cylindrical Taper Plug Gage - Morse WESTport Gage manufactures a complete line of standard taper ring and taper plug gages;Morse, Jarno, Brown & Sharpe, Jacobs, National Machine and any other special taper gage made to your blueprint specifications. WESTport also manufactures tapered arbors to...westportcorp.com

Bob Wright

Hawkeye

I was taught, back in the last century, that when the plies were compressed, any part of the rivet that protruded was to be cut off. the thickness of the set determined the proper length of the protrusion for proper head forming.Using a rivet set when fastening together 2, 3 or maybe 4 pieces of metal. You would give the end of the rivet a light smack to tighten it in the hole a bit, then you would place the hole over the rivet to drive all the pieces down on the rivet head before actually setting the rivet with a hammer or a gun.

Incidentally, up until recently, railroad bridges were to be fastened with rivets rather than bolts. The reason was that formn the head also increased the diameter of the rivet so it completely filled the hole. So, in theory, a 3/4" dia. rivet became 13/16" dia. after forming. Not sure this is still practiced today. been awhile since I was inteested in these things.

Bob Wright

caryc

Hawkeye

By your first sentance, I assume you were talking about a flush head rivet in the back, I wasn't. I was building airplanes not skyscrapers.I was taught, back in the last century, that when the plies were compressed, any part of the rivet that protruded was to be cut off. the thickness of the set determined the proper length of the protrusion for proper head forming.

Incidentally, up until recently, railroad bridges were to be fastened with rivets rather than bolts. The reason was that formn the head also increased the diameter of the rivet so it completely filled the hole. So, in theory, a 3/4" dia. rivet became 13/16" dia. after forming. Not sure this is still practiced today. been awhile since I was inteested in these things.

Bob Wright

- Joined

- Apr 2, 2014

- Messages

- 3,377

Looks "steeper" then any taper I'm familiar with?That is highly likely a correct description of what this does. It looks like one in the picture.

- Joined

- Apr 2, 2014

- Messages

- 3,377

The hole in the ends could be just center drilled to locate the bar for lathe turning it between centers and have nothing to do

with it's function. Agree it's some kind of "gauge" but still looks like too much angle for known tapers.

with it's function. Agree it's some kind of "gauge" but still looks like too much angle for known tapers.

Gage

I remember the Three Stooges playing Iron Workers.I was taught, back in the last century, that when the plies were compressed, any part of the rivet that protruded was to be cut off. the thickness of the set determined the proper length of the protrusion for proper head forming.

Incidentally, up until recently, railroad bridges were to be fastened with rivets rather than bolts. The reason was that formn the head also increased the diameter of the rivet so it completely filled the hole. So, in theory, a 3/4" dia. rivet became 13/16" dia. after forming. Not sure this is still practiced today. been awhile since I was inteested in these things.

Bob Wright

I didn't see all sides, but if there is a hole at the end of the shaft it could be a plumb bob

xtratoy

Buckeye

Still no response from the company that produced this item. I guess customer support isn't one of their big concerns.

Bob Wright

Hawkeye

Plumb bobs ususlly have a relatively sharp conicl point, this for exact centering over a benchmark.I didn't see all sides, but if there is a hole at the end of the shaft it could be a plumb bob

Years ago I was going to survey a prospective job site with an engineer who was from India. Had to pack the plumb bob in checked luggage, too dangerous for carry-on.

Bob Wright

caryc

Hawkeye

I wonder how many people have been killed with plumb bobs?Plumb bobs ususlly have a relatively sharp conicl point, this for exact centering over a benchmark.

Years ago I was going to survey a prospective job site with an engineer who was from India. Had to pack the plumb bob in checked luggage, too dangerous for carry-on.

Bob Wright

I am sticking with my 'tube centering device for a lathe.

Look here: https://www.ebay.com/itm/225940741366?itmmeta=01HXF8WTCD23RFJFK0VTHVDNQ7&hash=item349b1e1cf6:g:y8YAAOSwq1llk4Jt&itmprp=enc:AQAJAAAA8BQkwlgSXhfCiuLyENQkVGuO+lopPN5V4e4aIw8WsidHqmAlMn6rohhLS4aBIFl2z+hJtFirZl9ih8tjPpJO4XU6MuhQh7ByTjh6gsp8hLSJE5BRyew0S1mV76GVsKHW4x1OmD5xpTEadivPkFixGdw5yuAMii6bXH0Gf5B2fmG8hkHBLRAJZsVUvpicXOw8N5QRKcCyc436FBeuxsOrOSJmjkfPf69cOgsS3B4h1+iPpyTqlvcstxjF5hvNCggjyVrcrL+GPsJHuOQLZappEqfSQ55Lse9C+mZcETYjKG4AG0NsBjWH3T4mFpHYZrJicA==|tkp:BFBMwKbz6Otj

Look here: https://www.ebay.com/itm/225940741366?itmmeta=01HXF8WTCD23RFJFK0VTHVDNQ7&hash=item349b1e1cf6:g:y8YAAOSwq1llk4Jt&itmprp=enc:AQAJAAAA8BQkwlgSXhfCiuLyENQkVGuO+lopPN5V4e4aIw8WsidHqmAlMn6rohhLS4aBIFl2z+hJtFirZl9ih8tjPpJO4XU6MuhQh7ByTjh6gsp8hLSJE5BRyew0S1mV76GVsKHW4x1OmD5xpTEadivPkFixGdw5yuAMii6bXH0Gf5B2fmG8hkHBLRAJZsVUvpicXOw8N5QRKcCyc436FBeuxsOrOSJmjkfPf69cOgsS3B4h1+iPpyTqlvcstxjF5hvNCggjyVrcrL+GPsJHuOQLZappEqfSQ55Lse9C+mZcETYjKG4AG0NsBjWH3T4mFpHYZrJicA==|tkp:BFBMwKbz6Otj

As an eBay Associate we earn from qualifying purchases.

- Joined

- Apr 2, 2014

- Messages

- 3,377

Don't think so, what ever it is is designed to be hand held. If it was a lathe center it would most likely have a machined taperI am sticking with my 'tube centering device for a lathe.

Look here: https://www.ebay.com/itm/225940741366?itmmeta=01HXF8WTCD23RFJFK0VTHVDNQ7&hash=item349b1e1cf6:g:y8YAAOSwq1llk4Jt&itmprp=enc:AQAJAAAA8BQkwlgSXhfCiuLyENQkVGuO+lopPN5V4e4aIw8WsidHqmAlMn6rohhLS4aBIFl2z+hJtFirZl9ih8tjPpJO4XU6MuhQh7ByTjh6gsp8hLSJE5BRyew0S1mV76GVsKHW4x1OmD5xpTEadivPkFixGdw5yuAMii6bXH0Gf5B2fmG8hkHBLRAJZsVUvpicXOw8N5QRKcCyc436FBeuxsOrOSJmjkfPf69cOgsS3B4h1+iPpyTqlvcstxjF5hvNCggjyVrcrL+GPsJHuOQLZappEqfSQ55Lse9C+mZcETYjKG4AG0NsBjWH3T4mFpHYZrJicA==|tkp:BFBMwKbz6Otj

to match a tailstock or machined round to be clamped in a chuck. The knurling is a "give away" that it's made to be held.

There may be nobody left at the company that even has a clue what/who it was for.

As an eBay Associate we earn from qualifying purchases.

Bob Wright

Hawkeye

I think I've got it!

Insert the tapered portion into one end of a short section of black PVC pipe.

Then blow REALLY HARD on the other end.

Bob Wright

Insert the tapered portion into one end of a short section of black PVC pipe.

Then blow REALLY HARD on the other end.

Bob Wright