Scotch Brite (sp?) pads and then follow up with some Flitz or Mothers Magwheel Polish to get desired shine. I removed some old non--original parkerizing with the Scotch Brite pads. Worked great and very quick.

Interesting work and informative.

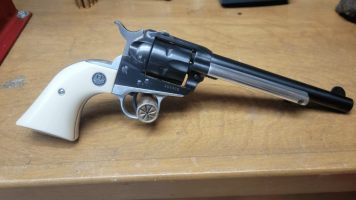

I didn't know Aluminum could be Parkerized. I suppose the Al is used to help lighten a pistol that weighs nearly 2 1/2 pounds. The fine folks at Ruger chose a good aircraft grade of Aluminum,

6061 T6 or the such. That alloy is tough in it's uncoated form and it does polish nicely, but it will scratch. Also, acidic perspiration

will tarnish it.

That alloy can be anodized with a highly polished clear coat offering a great deal of protection from scuffs and stains.

Finally I might mention that caustic (NaOH) stripping of anodizing removes a number of

thousandths of all surfaces outside and internal. If there are close toleranced applications, caustic stripping could ruin functionality.

I don't mean to be gabby, just a few things needed to be offered.